Personalized customization: 3DSL-360 & 3DSL-450

Small Batch production:?3DSL-600 & 3DSL-800

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? A batch of Nike shoes printed by SL 3D printer?in Shanghai center flagship store?

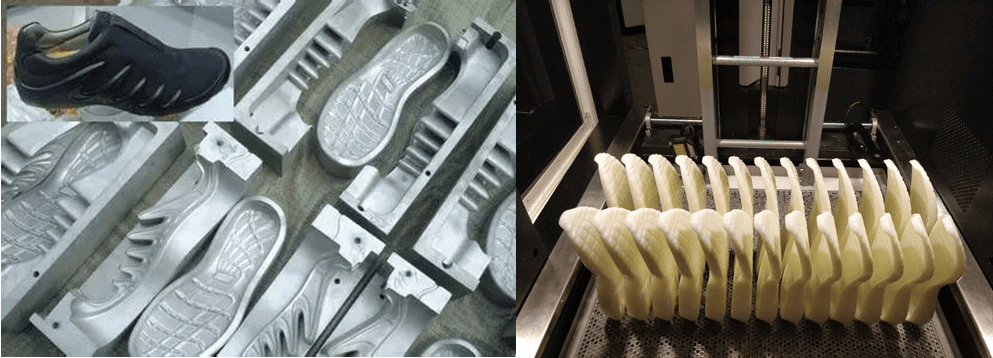

In recent years, 3D printing technology has gradually penetrated in the field of shoemaking. From kanban shoe molds to sanding shoe molds, to production molds, and even finished shoe soles, it seems that 3D printing technology can be seen everywhere. Although 3D printed shoes have not yet been popularized in shoe stores, due to the design potential and customization possibilities of 3D printed shoes, many shoe giants at home and abroad have frequently made efforts in this emerging technology field in recent years.

In the early stage of footwear design, shoe mold samples usually used traditional tools such as lathes, drill bits, punching machines, and molding machines. The production process was very time consuming and increased the time required for designing and verifying shoe molds. In contrast, 3D printing can automatically and quickly convert computer shoe samples into models, which not only overcomes the limitations of traditional processes, but also restores the design concept better, and cooperates with product testing and optimization.

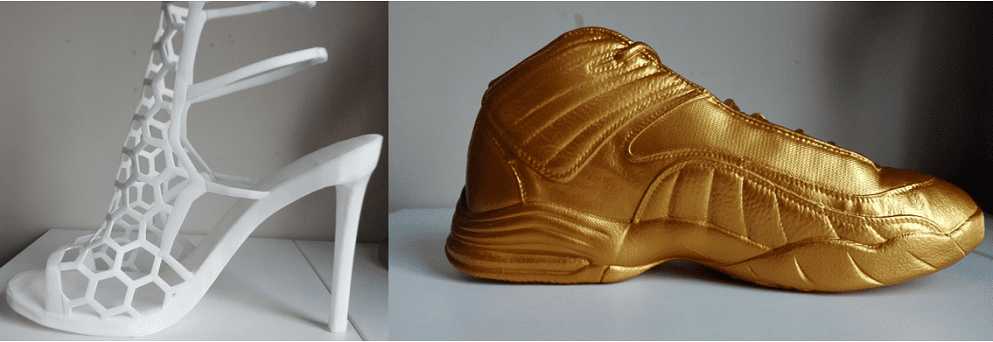

Based on the advantages of digital rapid production, 3D printing technology is not limited by structure, allowing designers to unleash their inspiration. In addition, 3D printing flexibility facilitates designers to modify designs and reduce upfront costs due to mold rework.

?it is expected that 3D printed shoes can be?personalized costomization for civilians. Usually, due to the cost of processes, raw materials, research and development, the price of customized shoes is much higher than that of ordinary shoes. 3D printing can reduce the cost of molds, shorten the development cycle and provide material utilization. In the future, it is expected to meet the individual needs of consumers in the production process while minimizing the production cost of enterprises.

3D printing is based on the 3D data information modeling of the customer's footsteps, and then uses the 3D printer to produce the insole, soles and shoes that fully conform to the customer's foot shape, speeding up the optimization of the product line, and bringing practical exercises to the personalized platform of the footwear industry.

Personalized customization: 3DSL-360 & 3DSL-450

Small Batch production:?3DSL-600 & 3DSL-800